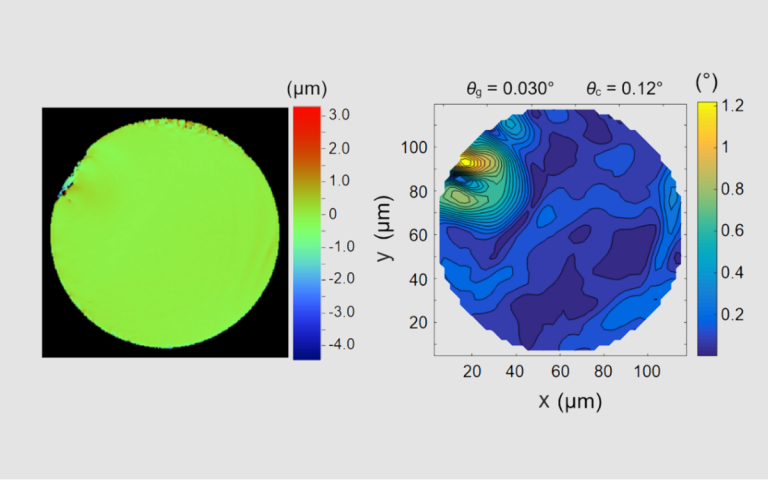

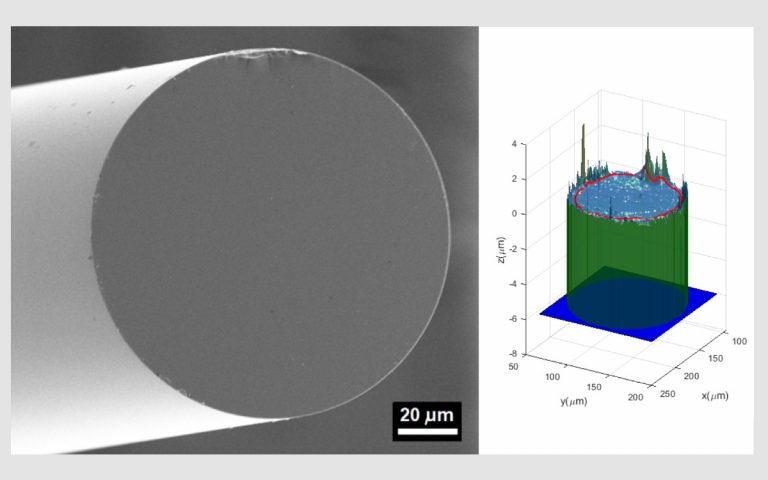

Fiber cleaving is an important technique in the area of fiber optics. A femtosecond laser-based scribing procedure has been demonstrated for cleaving silica optical fiber. As a proof of concept, SMF 28 fiber was scribed by femtosecond laser pulses and then placed under tension to initiate cleaving. The resulting end faces were measured using a noncontact optical interferometer. The laser-scribed fibers had a total height variation of 12 µm versus 17 µm for the mechanically scribed fibers and were free of rounding and melting around the edges. Thus the cleaved end face produced by femtosecond laser scribing has superior quality in terms of flatness, smoothness, and symmetry compared to mechanical scribing. The technique also has important potential advantages compared to laser cleaving based on melting. With further development, this technique has the potential to be used for automated cleaving of specialty fibers and multi-fiber arrays with comparable cleave quality.

- 100 fs – 20 ps 连续可调脉宽

- 最大单脉冲能量 4 mJ

- 最小脉宽输出 < 100 fs

- POD 和 BiBurst 功能

- 高达 5 次谐波或可调谐扩展

- CEP 稳定或重复频率锁定

- 热稳定性和密封设计

Quantifying end-face quality of cleaved fibers: Femtosecond laser versus mechanical scribing

M. A. A. Mamun, P. J. Cadusch, T. Katkus, S. Juodkazis, and P. R. Stoddart, Optics & Laser Technology 141, 107111 (2021).