Laser-induced photopolymerization, also known as direct laser lithography or direct laser writing, is a technique for the formation of three-dimensional (3D) micro- and nanostructures with variable architectures and subwavelength resolution.

The technique relies on a multiphoton absorption process in a material, such as photosensitive resin, typically transparent at the wavelength of laser radiation. The chemical change occurs at the laser focal spot via the absorption of two or more photons. The laser radiation is well-controlled for rapid prototyping of arbitrary 3D shapes with fine features. In particular, laser-induced photopolymerization is applied in the manufacturing of mesoscale optical, photonic, microfluidic components, as well as complex scaffolds for tissue engineering.

Laser-induced photopolymerization is associated mainly with petroleum-derived resins, but using bio-based materials obtained from renewable sources is becoming a trend. Such an environment-friendly approach offers easy processing, fulfills technological, functional, and durability requirements, and ensures increased bio-compatibility, recycling, and eventually lower cost. The research groups from Vilnius University and Kaunas University of Technology have recently employed a bio-based resin derived from soybean oil, which can be processed even without the addition of a photoinitiator. Their results show a high potential of the bio-based resins for high fidelity prototyping and additive manufacturing; see the publication for more details.

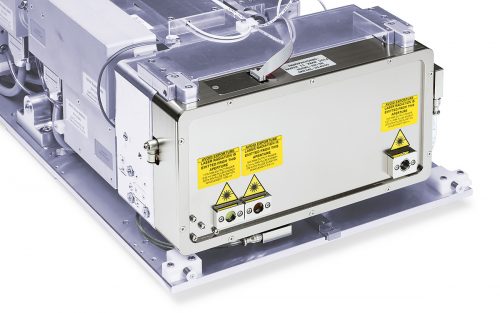

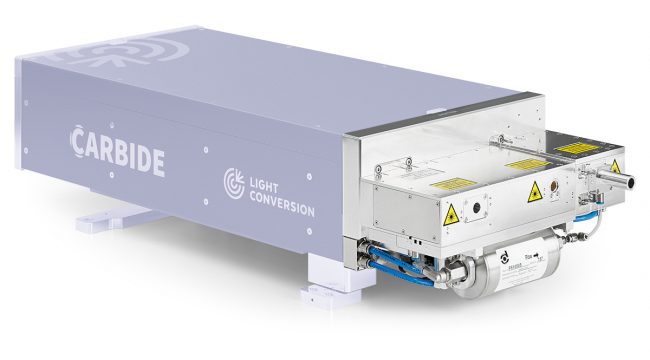

The photopolymerization is effectively obtained using PHAROS and CARBIDE series femtosecond lasers with their fundamental wavelength (1030 nm) or higher harmonics (515 nm, 343 nm), or wavelength-tunable industrial-grade I-OPA (320 – 10000 nm). High short- and long-term stability together with high beam quality ensure the robust and precise formation of the 3D micro- and nanostructures.

- 100 fs – 20 ps 连续可调脉宽

- 最大单脉冲能量 4 mJ

- 最小脉宽输出 < 100 fs

- POD 和 BiBurst 功能

- 高达 5 次谐波或可调谐扩展

- CEP 稳定或重复频率锁定

- 热稳定性和密封设计

- 515 nm, 343 nm, 257 nm 和 206 nm

- 软件选择输出波长

- 坚固耐用的工业级机械设计

- 190 fs – 20 ps 连续可调脉宽

- 最大输出 1 mJ @ 120 W 或 2 mJ @ 80 W

- 单脉冲 – 2 MHz 重复频率

- POD 和 BiBurst 功能

- 高达 5 次谐波或可调谐扩展

- 风冷型号

- 紧凑的工业级设计

- 515 nm, 343 nm 和 257 nm

- 软件选择输出波长

- 直接安装在激光器头上并集成一体式

- 坚固耐用的工业级机械设计

- 50 W 紫外型号

- 坚固的工业级机械设计

- 单箱式解决方案

- 可调谐或固定波长型号

- 即插即用、安装简洁、性能强大

- 市场上最紧凑的 OPA

- 11 Mhz、40 Mhz 或 76 Mhz 的重复频率

- <50 fs 的脉宽

- 最高可达 20 W 的高功率型号

- 最高可达 0.6 µJ 的高能量型号

- 高输出稳定性的工业级设计

- CEP 稳定或重复频率锁定

3D nanopolymerization and damage threshold dependence on laser wavelength and pulse duration

D. Samsonas, E. Skliutas, A. Čiburys, L. Kontenis, D. Gailevičius, J. Berzinš, D. Narbutis, V. Jukna, M. Vengris, S. Juodkazis et al., Nanophotonics 0 (0) (2023).

X-photon laser direct write 3D nanolithography

E. Skliutas, D. Samsonas, A. Čiburys, L. Kontenis, D. Gailevičius, J. Berzinš, D. Narbutis, V. Jukna, M. Vengris, S. Juodkazis et al., Virtual and Physical Prototyping 1 (18), e2228324 (2023).

An Improved Transwell Design for Microelectrode Ion-Flux Measurements

B. Buchroithner, P. Spurný, S. Mayr, J. Heitz, D. Sivun, J. Jacak, and J. Ludwig, Micromachines 3 (12), 273 (2021).

Birefringent optical retarders from laser 3D-printed dielectric metasurfaces

S. Varapnickas, S. C. Thodika, F. Moroté, S. Juodkazis, M. Malinauskas, and E. Brasselet, Applied Physics Letters 15 (118), 151104 (2021).

Dual Channel Microfluidics for Mimicking the Blood–Brain Barrier

B. Buchroithner, S. Mayr, F. Hauser, E. Priglinger, H. Stangl, A. R. Santa‑Maria, M. A. Deli, A. Der, T. A. Klar, M. Axmann et al., 2 (15), 2984-2993 (2021).

Focal spot optimization through scattering media in multiphoton lithography

B. Buchegger, A. Haghofer, D. Höglinger, J. Jacak, S. Winkler, and A. Hochreiner, Optics and Lasers in Engineering 142, 106607 (2021).

Vegetable Oil-Based Thiol-Ene/Thiol-Epoxy Resins for Laser Direct Writing 3D Micro-/Nano-Lithography

S. Grauzeliene, A. Navaruckiene, E. Skliutas, M. Malinauskas, A. Serra, and J. Ostrauskaite, Polymers 6 (13), 872 (2021).

3D multiphoton lithography using biocompatible polymers with specific mechanical properties

B. Buchroithner, D. Hartmann, S. Mayr, Y. J. Oh, D. Sivun, A. Karner, B. Buchegger, T. Griesser, P. Hinterdorfer, T. A. Klar et al., Nanoscale Advances 6 (2), 2422-2428 (2020).

A Bio-Based Resin for a Multi-Scale Optical 3D Printing

E. Skliutas, M. Lebedevaite, S. Kasetaite, S. Rekštytė, S. Lileikis, J. Ostrauskaite, and M. Malinauskas, Scientific Reports 1 (10) (2020).

Dynamic voxel size tuning for direct laser writing

T. Tičkūnas, D. Paipulas, and V. Purlys, Optical Materials Express 6 (10), 1432 (2020).