Nanotechnology and lasers are among the most successful and active fields of research and technology in the past decades and provide great potential when merged together. Several laser-based techniques enable surface nanostructuring of metal, semiconductor, or even glass, which are then employed in sensing, imaging, solar energy, and biomedicine. Such laser-based techniques include but are not limited to the formation of laser-induced periodic surface structures (LIPSS), laser interference lithography (LIL), and direct laser interference patterning (DLIP), and will be shortly introduced next.

Formation of LIPSS, also known as ripples or nanoripples, is a direct laser writing technique for manufacturing grating-like nanostructures. LIPSS originate from the interference of the incident/refracted laser light with the scattered or diffracted light near the surface. The technique has gained a lot of interest due to its simplicity and robustness as its manufacturing can be performed in ambient air and is fully compatible with industrial demands on costs, reliability, and productivity. Depending on the selected materials and irradiation conditions, the processing of LIPSS enables various types of surface functionalization through different period, ranging from few tens of nanometers to several micrometers.

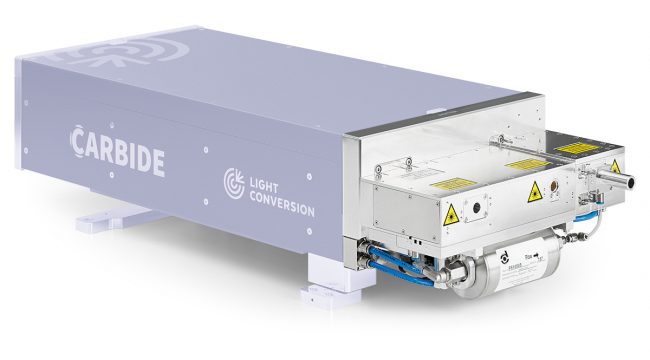

The other two methods, LIL and DLIP, rely on laser interference of incident laser light. Two or more laser beams are superimposed in spatial and temporal domain; thus, creating an interference pattern with its period down to a subwavelength scale. In LIL, the pattern is first recorded in a light-sensitive medium and then transferred into the material of interest. On the contrary, DLIP enables a direct structuring of material. At the right irradiation conditions, the surface gets melted or even ablated at the peaks of intensity. Given the inherently large spectral bandwidth of ultrashort laser pulses and its impact on the resulting interference patterns, the LIL and DLIP techniques are often limited to pulse duration in the ps-range or longer. However, this is not an issue with the tunability of pulse duration up to 20 ps – a unique feature of PHAROS and CARBIDE femtosecond lasers.

When choosing the technique for the application of interest, the user has to consider several aspects. First, in LIL and DLIP, the period of the interference pattern is controlled by the wavelength of laser irradiation and the angle of incidence between the interfering beams. However, the minimum period is limited by the optical diffraction limit. Thus, if sub-100 nm feature size is desired, one should go with LIPSS. Another aspect to consider is the modulation depth of the nanostructured pattern. The depth of the DLIP pattern can be independently controlled by the laser pulse energy and the number of pulses applied. Even though similar relation is expected for LIPSS, it is typically more difficult to control. DLIP structures can have significantly larger modulation depths and regularity over a large area.

The nanostructured surfaces are widely used in sensing, e.g., surface-enhanced Raman spectroscopy (SERS), where a roughened metallic surface enhances the Raman scattering of the adsorbed analyte molecules by several orders of magnitude. Also, nanostructured materials, such as black silicon, have found interest in the market of photodetectors and solar cells. The micrometric silicon spikes trap the incident light, subsequently, providing high absorptance in the visible and infrared spectral ranges. Furthermore, LIPSS and other nanostructuring techniques enable hydrophobic and hydrophilic surfaces for automotive and aerospace engineering, antibacterial and cell-repellent or cell-stimulating surfaces for medical applications, and many other ingenious applications.

PHAROS and CARBIDE femtosecond lasers are widely used for the aforementioned surface nanostructuring techniques, heavily participating in developing future technologies and exploring novel surface functionalities.

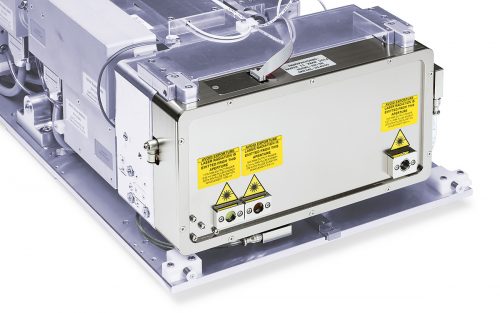

- 100 fs – 20 ps 连续可调脉宽

- 最大单脉冲能量 4 mJ

- 最小脉宽输出 < 100 fs

- POD 和 BiBurst 功能

- 高达 5 次谐波或可调谐扩展

- CEP 稳定或重复频率锁定

- 热稳定性和密封设计

- 515 nm, 343 nm, 257 nm 和 206 nm

- 软件选择输出波长

- 坚固耐用的工业级机械设计

- 190 fs – 20 ps 连续可调脉宽

- 最大输出 1 mJ @ 120 W 或 2 mJ @ 80 W

- 单脉冲 – 2 MHz 重复频率

- POD 和 BiBurst 功能

- 高达 5 次谐波或可调谐扩展

- 风冷型号

- 紧凑的工业级设计

- 515 nm, 343 nm 和 257 nm

- 软件选择输出波长

- 直接安装在激光器头上并集成一体式

- 坚固耐用的工业级机械设计

- 50 W 紫外型号

Direct correlation of local fluence to single-pulse ultrashort laser ablated morphology

H. Sakurai, K. Konishi, H. Tamaru, J. Yumoto, and M. Kuwata‑Gonokami, Communications Materials 1 (2) (2021).

Direct Femtosecond Laser Fabrication of Chemically Functionalized Ultra-Black Textures on Silicon for Sensing Applications

Y. Borodaenko, S. Gurbatov, M. Tutov, A. Zhizhchenko, S. A. Kulinich, A. Kuchmizhak, and A. Mironenko, Nanomaterials 2 (11), 401 (2021).

Direct Laser Writing for the Formation of Large-Scale Gold Microbumps Arrays Generating Hybrid Lattice Plasmon Polaritons in Vis–NIR Range

E. Stankevičius, K. Vilkevičius, M. Gedvilas, E. Bužavaitė‑Vertelienė, A. Selskis, and Z. Balevičius, Advanced Optical Materials, 2100027 (2021).

Femtosecond Laser-Induced Periodic Surface Structures on 2D Ti-Fe Multilayer Condensates

O. V. Kuznietsov, G. D. Tsibidis, A. V. Demchishin, A. A. Demchishin, V. Babizhetskyy, I. Saldan, S. Bellucci, and I. Gnilitskyi, Nanomaterials 2 (11), 316 (2021).

Laser Nanostructuring for Diffraction Grating Based Surface Plasmon-Resonance Sensors

I. Gnilitskyi, S. V. Mamykin, C. Lanara, I. Hevko, M. Dusheyko, S. Bellucci, and E. Stratakis, Nanomaterials 3 (11), 591 (2021).

Morphological Study of Nanostructures Induced by Direct Femtosecond Laser Ablation on Diamond

A. Abdelmalek, A. N. Giakoumaki, V. Bharadwaj, B. Sotillo, T. L. Phu, M. Bollani, Z. Bedrane, R. Ramponi, S. M. Eaton, and M. Maaza, Micromachines 5 (12), 583 (2021).

Rewritable and Tunable Laser-Induced Optical Gratings in Phase-Change Material Films

P. I. Trofimov, I. G. Bessonova, P. I. Lazarenko, D. A. Kirilenko, N. A. Bert, S. A. Kozyukhin, and I. S. Sinev, 27 (13), 32031-32036 (2021).

Slow speed friction behaviour of a-C:H with different fs-laser micro-patterns against diamond tip in hyaluronic acid

A. Dorner‑Reisel, C. Schürer, A. Engel, H. Albrecht, S. Svoboda, and S. Weißmantel, 735, 138863 (2021).

Ultrastiff graphene

V. Hiltunen, P. Koskinen, K. K. Mentel, J. Manninen, P. Myllyperkiö, M. Pettersson, and A. Johansson, npj 2D Materials and Applications 1 (5) (2021).

Controlling the wettability of stainless steel from highly-hydrophilic to super-hydrophobic by femtosecond laser-induced ripples and nanospikes

A. Žemaitis, A. Mimidis, A. Papadopoulos, P. Gečys, G. Račiukaitis, E. Stratakis, and M. Gedvilas, RSC Advances 62 (10), 37956-37961 (2020).