Stainless steel polishing is a finishing technique to achieve a specific or unique finish to a metal surface.

Stainless steel is a widely used alloy with rust-free and heat-resistant properties. Various applications, from consumer electronics to medical tools manufacturing, use stainless steel. Femtosecond lasers can engrave numerous types of stainless steel and change its surface properties.

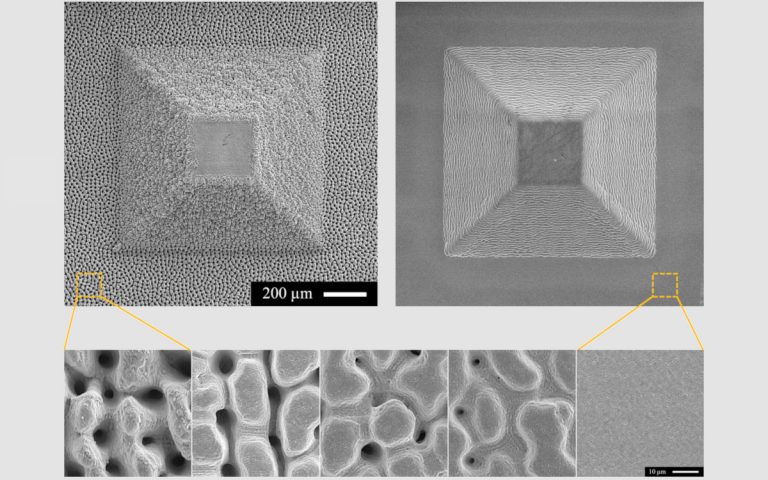

Ultrashort pulsed laser radiation forms a typical micro-cone structure. The measured roughness of the structure is Sa approx. 6 µm, Sq approx. 8 µm and Sz over 30 µm. As a result, the bottom of the structure looks dark grey and does not have a metallic shine. It is possible to completely smooth the micro-cone structure by subsequent smoothing with GHz burst mode. This smoothing results in roughness with Sa and Sq below 0.2 µm and Sz below 2 µm.

- 190 fs – 20 ps 连续可调脉宽

- 最大输出 1 mJ @ 120 W 或 2 mJ @ 80 W

- 单脉冲 – 2 MHz 重复频率

- POD 和 BiBurst 功能

- 高达 5 次谐波或可调谐扩展

- 风冷型号

- 紧凑的工业级设计

- 100 fs – 20 ps 连续可调脉宽

- 最大单脉冲能量 4 mJ

- 最小脉宽输出 < 100 fs

- POD 和 BiBurst 功能

- 高达 5 次谐波或可调谐扩展

- CEP 稳定或重复频率锁定

- 热稳定性和密封设计

Optimization of the ablation process using ultrashort pulsed laser radiation in different burst modes

D. Metzner, P. Lickschat, and S. Weißmantel, Journal of Laser Applications 1 (33), 012057 (2021).

High-quality surface treatment using GHz burst mode with tunable ultrashort pulses

D. Metzner, P. Lickschat, and S. Weißmantel, Applied Surface Science 531, 147270 (2020).